Introduction

FreeCAD is a powerful, open-source 3D computer-aided design (CAD) software that has gained popularity among makers, hobbyists, and professionals alike. One of its notable features is its ability to seamlessly integrate with 3D printing technology, making it an excellent choice for creating and printing complex designs. In this article, we’ll delve into the best practices for using FreeCAD for 3D printing, covering essential topics such as design principles, modeling techniques, and post-processing tips.

Setting Up FreeCAD for 3D Printing

Before diving into the world of 3D printing with FreeCAD, it’s essential to set up the software correctly. Here’s a step-by-step guide to get you started:

Installing FreeCAD

To begin, download the latest version of FreeCAD from the official website. The software is available for Windows, macOS, and Linux platforms. Once downloaded, follow the installation instructions for your operating system.

Configuring FreeCAD for 3D Printing

After installation, launch FreeCAD and navigate to “Settings” > “Configure” > “General.” In the “Default Units” section, set the units to “mm” (millimeters) to ensure accurate measurements for 3D printing. Additionally, set the “Precision” to “4” to achieve the desired level of detail in your designs.

Design Principles for 3D Printing

When designing for 3D printing, it’s crucial to follow certain principles to ensure successful prints. Here are some essential tips to keep in mind:

Understanding 3D Printing Terminology

Before diving into design, familiarize yourself with basic 3D printing terminology. Key terms include:

- Infill: The internal structure of a 3D printed object, which can be adjusted to reduce weight or increase strength.

- Perimeter: The outer boundary of a 3D printed object, which can be adjusted to change the object’s appearance.

- Shell: The outer layer of a 3D printed object, which can be adjusted to change the object’s thickness.

Designing for 3D Printing

When designing for 3D printing, consider the following factors:

- Resolution: The level of detail in your design, which can be affected by the 3D printer’s resolution and layer height.

- Support material: The material used to support overhanging features or complex geometries, which can be adjusted to reduce waste and improve print quality.

- Orientation: The way your design is oriented on the print bed, which can affect print quality, warping, and adhesion.

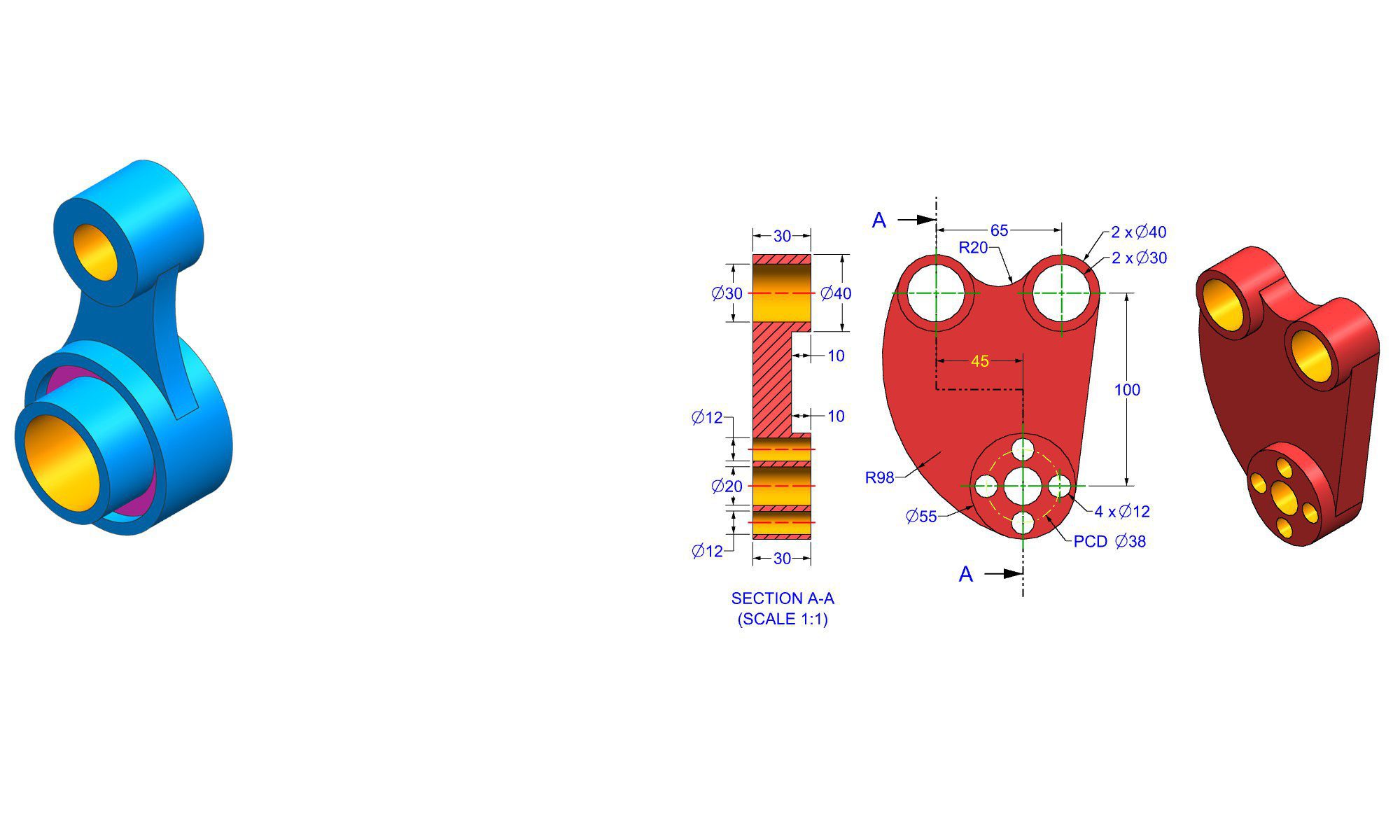

Modeling Techniques for 3D Printing

FreeCAD offers a range of modeling techniques that can help you create complex designs for 3D printing. Here are some essential techniques to master:

Working with Primitives

FreeCAD’s primitive shapes (e.g., cubes, spheres, cylinders) can be combined to create complex designs. Use the “Part” workbench to manipulate and combine primitive shapes.

Using the Part Design Workbench

The Part Design workbench allows you to create custom shapes using parametric modeling. Use this workbench to create complex geometries, such as holes, slots, and chamfers.

Applying Materials and Finishes

FreeCAD allows you to apply materials and finishes to your designs, simulating real-world materials and effects. Use this feature to visualize your designs in various materials and finishes.

Post-Processing Tips for 3D Printing

After printing, it’s essential to post-process your designs to achieve the desired finish and quality. Here are some essential tips to follow:

Sanding and Smoothing

Use a sanding block or a Dremel tool to smooth out rough edges and surfaces. Apply a coat of primer or paint to enhance the finish.

Removing Support Material

Use a hobby knife or a razor blade to carefully remove support material from your design. Be gentle to avoid damaging the surrounding material.

Applying Finishing Coats

Apply a clear coat or a paint to enhance the finish and protect the material from damage.

Troubleshooting Common Issues

As with any 3D printing software, you may encounter common issues that can be resolved by following these troubleshooting tips:

Issues with Infill

If your infill is not printing correctly, check the “Infill” settings in the “Settings” menu. Adjust the infill density and pattern to achieve the desired effect.

Issues with Support Material

If your support material is not printing correctly, check the “Support” settings in the “Settings” menu. Adjust the support material type and density to achieve the desired effect.

Issues with Orientation

If your object is not printing correctly due to orientation, try rotating the object by 90 degrees or using the “Mirror” feature to create a mirror image.

Conclusion

Using FreeCAD for 3D printing is an excellent way to create complex designs and prints with ease. By following the best practices outlined in this article, you’ll be well on your way to mastering the software and achieving professional-quality prints. Remember to experiment with different design principles, modeling techniques, and post-processing tips to push the boundaries of what’s possible with 3D printing.

FAQ

What is the best way to export a 3D model from FreeCAD for 3D printing?

Export your 3D model as an STL file using the “Export” feature in the “Part” workbench. This file format is widely supported by 3D printing software and slicers.

How do I create a custom 3D printing profile in FreeCAD?

To create a custom 3D printing profile, navigate to “Settings” > “Configure” > “Add Printer.” Select the 3D printer model and follow the on-screen instructions to configure the profile.

Can I use FreeCAD for other applications besides 3D printing?

Yes, FreeCAD is a versatile CAD software that can be used for various applications, including architectural design, mechanical engineering, and product design.

How do I troubleshoot issues with my 3D prints?

Check the “Diagnostic” menu in the “Settings” menu to troubleshoot common issues with your 3D prints. You can also consult the FreeCAD community forums for help and support.

Can I use FreeCAD to create 3D models from scratch?

Yes, FreeCAD offers a range of tools and features to create 3D models from scratch. Use the “Part” workbench to create custom shapes and the “Part Design” workbench to create complex geometries.

Is FreeCAD free and open-source?

Yes, FreeCAD is a free and open-source CAD software that can be downloaded and used by anyone. The software is developed by a community of volunteers and contributors.

End of Blog

FREECAD All-in-One Workbook

500+ Practice Exercises to Master FreeCAD through real-world practice!

This all-in-one workbook is your ultimate resource to develop hands-on CAD skills with FreeCAD. Whether you’re a student, engineer, hobbyist, or professional, this guide is built to help you gain real design confidence through structured practice.

What’s Inside this Book:

- 200 2D Sketching Exercises – Build a strong foundation in dimension-driven 2D geometry and technical drawings

- 200 3D Modeling Exercises – Practice modeling real-world parts, from simple shapes to complex components.

- Multi-Part Assembly Projects – Understand how parts fit together and create full assemblies with detailed drawings

🎯 Why This Book?

- 500+ practice exercises following real design standards

- Designed for self-paced learning & independent practice

- Perfect for classrooms, technical interview preparation, and personal projects

- Covers 2D Sketching, 3D Modeling & Assembly Design in one workbook

- Trusted by 15,000+ CAD learners worldwide