Autodesk Inventor: Powerful 3D CAD Software for Mechanical Design and Engineering

Autodesk Inventor is a professional-grade 3D CAD software widely used for mechanical design, product development, and engineering simulations. Developed by Autodesk, Inventor enables engineers and designers to create accurate 3D models, assemblies, and technical drawings with precision and efficiency. It is especially popular in manufacturing, automotive, aerospace, and industrial design industries.

In this in-depth guide, we’ll explore what Autodesk Inventor is, its core features, benefits, use cases, and why it remains one of the most trusted CAD tools for mechanical engineers worldwide.

What Is Autodesk Inventor?

Autodesk Inventor is a parametric, feature-based 3D mechanical design software that helps professionals design, visualize, and simulate products before they are built. It supports the complete product development lifecycle—from conceptual design and prototyping to manufacturing and documentation.

Inventor is available for Windows and integrates seamlessly with other Autodesk products such as AutoCAD, Fusion 360, and Vault, making it a strong choice for enterprise-level workflows.

Why Choose Autodesk Inventor?

Autodesk Inventor stands out for its advanced mechanical design tools, reliability, and deep integration with manufacturing processes.

1. Industry-Standard Mechanical CAD

Inventor is widely adopted across industries, making it easier to collaborate, hire skilled professionals, and exchange files with partners.

2. Parametric and Direct Modeling

Users can work with parametric constraints or switch to direct modeling for faster design iterations.

3. Professional Simulation Tools

Built-in stress analysis, motion simulation, and interference detection help validate designs before production.

4. Seamless Autodesk Ecosystem

Inventor integrates tightly with AutoCAD, Fusion 360, and Autodesk Vault for data management and collaboration.

Key Features of Autodesk Inventor

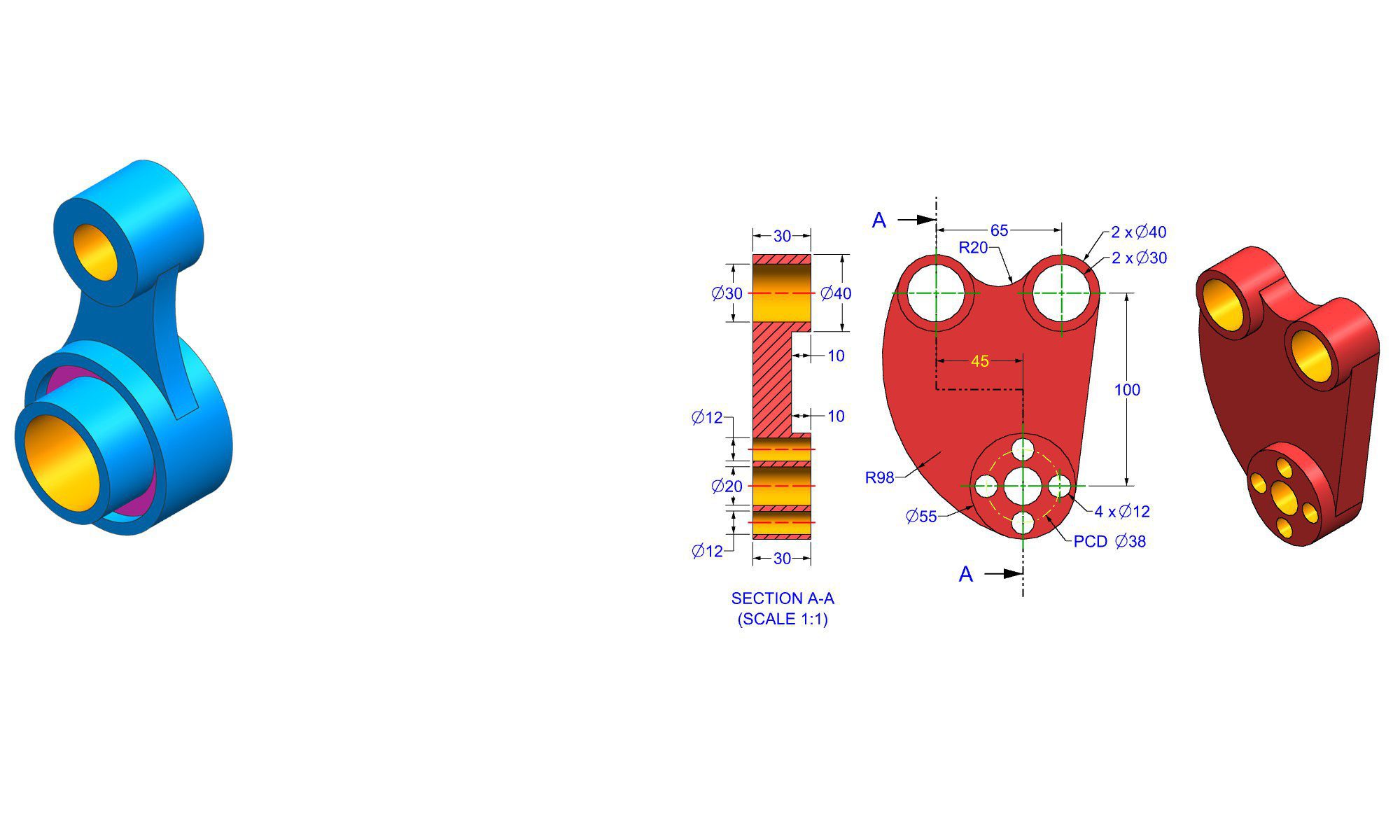

Parametric 3D Modeling

Inventor allows designers to define dimensions, constraints, and relationships, enabling easy updates and revisions throughout the design process.

Assembly Design and Management

Create complex assemblies with thousands of components while maintaining performance and design accuracy. Tools like constraints, joints, and contact sets ensure proper mechanical behavior.

Drawing and Documentation

Generate 2D drawings, exploded views, and bills of materials (BOMs) directly from 3D models, ensuring consistency and reducing errors.

Built-In Simulation and Analysis

Inventor includes tools for:

-

Stress and deformation analysis

-

Motion simulation

-

Dynamic loads testing

These features help reduce prototyping costs and improve product reliability.

Sheet Metal and Frame Design

Specialized tools allow users to design sheet metal parts, folded components, and structural frames with manufacturing-ready outputs.

iLogic Automation

Inventor’s iLogic feature enables rule-based automation, helping companies standardize designs and reduce repetitive tasks.

File Format Compatibility

Autodesk Inventor supports a wide range of industry-standard file formats, including:

-

DWG

-

DXF

-

STEP

-

IGES

-

STL

This ensures smooth collaboration with suppliers, manufacturers, and other CAD platforms.

Common Use Cases of Autodesk Inventor

Mechanical Engineering

Inventor is extensively used for designing machinery, tools, and mechanical components with high precision.

Product Design and Manufacturing

From consumer products to industrial equipment, Inventor supports detailed modeling and manufacturing-ready designs.

Automotive and Aerospace

Engineers use Inventor to design parts, assemblies, and systems that require high accuracy and simulation validation.

Sheet Metal Fabrication

Inventor’s sheet metal tools help generate flat patterns and production-ready designs for fabrication.

Education and Professional Training

Inventor is widely taught in engineering colleges and technical institutes, preparing students for real-world industry demands.

Autodesk Inventor vs Other CAD Software

When compared to tools like SolidWorks, Fusion 360, or FreeCAD, Autodesk Inventor excels in professional mechanical workflows.

-

Compared to Fusion 360: Inventor is more powerful for large assemblies and enterprise-level mechanical design.

-

Compared to SolidWorks: Inventor offers comparable features with tighter AutoCAD integration.

-

Compared to FreeCAD: Inventor provides a more polished UI, advanced simulations, and official technical support.

While Inventor is a paid tool, its feature depth justifies the investment for professional users.

Advantages of Autodesk Inventor

-

Professional-grade mechanical CAD tools

-

Advanced simulation and analysis

-

Strong assembly and documentation capabilities

-

Excellent integration with Autodesk products

-

Widely recognized in the engineering industry

Limitations of Autodesk Inventor

Despite its strengths, Inventor has some limitations:

-

Subscription-based pricing can be expensive

-

Available only on Windows

-

Requires powerful hardware for large assemblies

However, for professional engineering environments, these limitations are often outweighed by its capabilities.

Getting Started With Autodesk Inventor

To begin using Autodesk Inventor:

-

Download Inventor from Autodesk’s official website

-

Choose a subscription or educational license

-

Learn basic sketching, constraints, and assemblies

-

Explore Autodesk tutorials and official documentation

With practice, Inventor becomes an extremely efficient tool for complex mechanical design tasks.

Final Thoughts

Autodesk Inventor is one of the most powerful 3D CAD software solutions for mechanical engineering and product design. Its parametric modeling, advanced simulation tools, and seamless integration with the Autodesk ecosystem make it a top choice for professionals and enterprises.

If you are working on complex mechanical assemblies, manufacturing-ready designs, or engineering simulations, Autodesk Inventor provides the reliability, precision, and scalability required for modern product development.